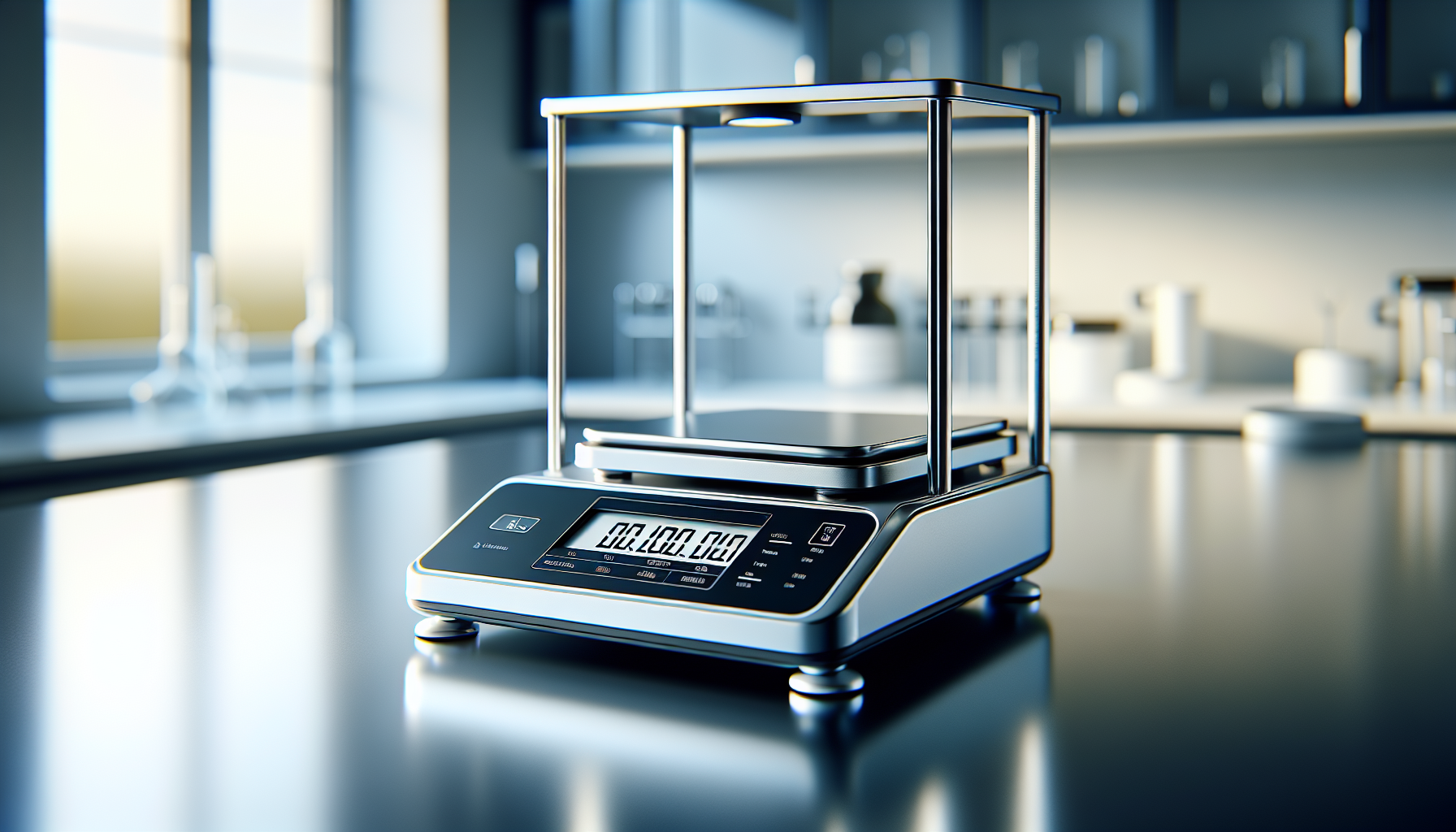

An analytical balance, with readability up to 0.1 mg, is an invaluable instrument when it comes to precise measurements and quantitative chemical analysis for a variety of solid objects, powders, liquids or granular substances. This precision measuring device plays a major role in ensuring accuracy and consistency as its quality and performance are paramount factors influencing the end results obtained from different industries.

Key Takeaways

-

Analytical balances are highly precise weighing devices which offer capabilities such as parts counting and check weighing.

-

They are essential for ensuring accuracy in food production, pharmaceutical development, quality control and scientific results.

-

Analytical balances feature user-friendly interfaces, advanced functions for complex tasks and customizable features to improve data security.

Exploring the Fundamentals of Analytical Balances

Weighing with precision requires the use of an analytical balance, which utilizes technology like magnetic force restoration to guarantee highly accurate results. Air currents and temperature fluctuations can affect this accuracy when using a stainless steel weighing pan. With capabilities such as parts counting, percent weighing check weights differential and dynamic weighing, the flagship balances from Ohaus are specifically designed for routine weighings that require extremely precise measurement values. The Explorer Analytical Balance surpasses all other weight measuring devices due to its capacity for extreme accuracy in spite of varying conditions!

Importance of Precision in Weighing

The requirement for precise weighing is paramount, as variations in weight can have major ramifications on scientific experiments or production procedures. This degree of accuracy is especially pertinent to pharmaceuticals where even a minor change of 1mg could affect the product’s efficacy and effectiveness.

Consistent measurements are fundamental for sustaining quality assurance and reliability when it comes to results, making precision necessary from both practicality and safety standpoints. Upholding high standards through stringent weighings serves an integral role in many industries today.

The Various Applications of Analytical Balances Across Industries

Analytical balances have established themselves as indispensable pieces of equipment in a number of industries. For instance, they are used to guarantee precision and accuracy when employed by the pharmaceutical industry, food production businesses or plastic/chemical makers for quality assurance tests and calibration measurements. The versatility that these balances bring makes them invaluable components within those fields where an exact assessment is paramount. Their precision ensures reliable results can be delivered accurately each time they’re utilized. Emphasizing why analytical scales need to remain part of any extensive technical set-up across various sectors such as specified before.

Key Roles in Pharmaceutical Development

Analytical balances are highly valuable in the pharmaceutical sector because they offer ultra-accurate measurements, measured in different units such as ounces. These precise scales play a major role not only with quality control and formulation, but also when it comes to safety, efficacy, consistency of formulations plus meeting up regulatory compliances while being cost effective too. With analytical balances one can have confidence that measurements will be done correctly, which is an absolute must in this industry.

Ensuring Accuracy in Food Production

Analytical balances are essential in food production due to their ability to provide precise measurements. These specialized scales enable accurate ingredient weighting, quality control and adherence to standards during the manufacturing process of edible products such as baked goods, which necessitate more reliable measures than volume alone.

Optimizing Balance Placement for Accurate Results

Achieving precise results from an analytical balance hinges on its appropriate placement. The laboratory should be kept out of direct sunlight and ideally have a stable temperature. The balance itself must also not be exposed to environmental conditions which could compromise accuracy.

Shielding from Environmental Interferences

The precision of an analytical balance is susceptible to environmental factors such as air currents, temperature changes and vibrations. To keep the display steady, it’s important that these disturbances be blocked from reaching the scale by placing it in a location away from any drafts or fluctuations. Doing so will help ensure accurate readings are obtained with no interference.

Selecting the Ideal Laboratory Space

When it comes to picking the right laboratory for balancing analytical scales, a variety of criteria must be taken into consideration. Cleanliness and stability of location are paramount. Accessibility, size/design, safety features and power supply are all necessary components. This applies specifically when weighing items up to 220 g, as special conditions must be maintained in order for maximum accuracy on balances. These include temperature levels between 20-25°C with 40-60% humidity plus minimal air flow ensuring that each balance remains level upon a clean surface area within said room. Such details need also address potential future expansions regarding data management concerning these precision instruments.

Calibration: The Key to Reliable Measurements

Performing regular calibration checks is an essential procedure for ensuring the accuracy and dependability of any analytical balance. This entails comparing the values generated by the said device to those of a standard test weight that has been confirmed as accurate. In this way, one can confirm if the readings being provided are precise, thereby reinforcing its reliability in terms of weighing.

The Process of Internal Calibration

The technique of internal calibration allows a balance to automatically adjust itself without the need for manual input. This method is known as an advanced form and involves weights within the unit that will ensure accuracy in measurements taken with it. Through regular calibration of such balances, its precision can be kept intact, which leads to consistent outcomes from tests conducted on them.

Scheduling Regular Calibration Checks

Maintaining balance accuracy and compliance with industry standards requires regular calibration checks. This allows us to assess the measurement quality of the samples weighed by it, guaranteeing an accurate result. Ideally, this should be done at least once annually. Make sure to check manufacturer’s instructions as they may provide more detailed advice for specific balances. Keeping track of such calibrations is vital in order preserve precision and assure reliability throughout its use over time. At Data Support Company we offer first class calibration service for all balances and scales. Our laboratory is accredited in accordance with the recognized International Standard ISO/IEC 17025:2017.

Technological Advancements in Analytical Balances

Analytical balances have seen considerable advancements in recent years, incorporating the integration of AI as well as accelerated technology breakthroughs. As a result, measurements are more exact and laboratories boast greater quality control.

Integrating Data Transfer Solutions

Data transfer technologies have totally transformed the way data is managed in laboratories. These solutions provide a fast and protected method to retrieve information from balance scales, aiding with storing, ordering and sharing of this data plus enhancing reporting processes within labs. The incorporation of 0.1 mg weight brings more use for balances as lab tools even ahead.

User-Friendly Interfaces for Enhanced Usability

Modern analytical balances are incredibly advanced in terms of features and capabilities, but also offer users a simple interface for ease-of-use. The backlit LCD screen with its color touchscreen display makes accuracy more achievable when operating the balance within laboratories or other facilities. These user friendly systems allow personnel to manage data quickly while still having access to all relevant information they need through their use of the LCD panels on each individual balance itself.

Versatility in Measurement: Beyond Simple Weighing

Analytical balances provide much more than merely weighing capabilities. They have a wide range of additional functions, including temperature and humidity measurements, density probes for samples, as well as ionizers, all to support various activities like research or production control in terms of quality assurance. This versatility makes them suitable for use across different industries.

Advanced Functions for Complex Tasks

Analytical balances are renowned for their advanced capabilities that allow them to do more than just weigh things. For example, the parts counting feature of these scales is very useful as it uses weight-based calculations to determine how many items there are in a sample by dividing its total mass with each individual item’s corresponding weight. This way, analytical balances can accurately work out the number of components included without difficulty. Since this technology allows weighing up accuracy and precision levels which could not be achieved via traditional methods before now have become possible thanks to analytical balance systems.

Adapting to Various Units of Measurement

Analytical balances offer a wide array of measurement units, such as grams, kilograms, pounds, newtons, grains and ounces. This range enables scientists to precisely define the quantity they are examining in an understandable way, which adds more meaning to their research data. As a result of this feature on analytical balances, it is possible for researchers to assess all relevant metrics with greater precision and accuracy than ever before.

Durability and Design Considerations

When selecting an analytical balance for a laboratory, design and durability should be taken into account. To promote reliability and guarantee its long-term use in such settings, stainless steel or glass components are essential features of the construction to make sure it can manage regular activity without becoming damaged.

The Role of Stainless Steel and Glass in Balance Design

In analytical balances, stainless steel and glass play a crucial role in the design. With its resistance to corrosion, stainless steel is ideal for use in laboratory settings where exposure to chemicals or moisture could occur regularly. The transparent construction of glass provides an impermeable shield over the weighing area and helps deter air movement that can interfere with this delicate process. Both materials make up essential components when it comes to designing modern-day precision balances.

Maintenance Tips for Long-Term Performance

Maintaining the balance is a must in order to guarantee its optimal and prolonged functioning. To accomplish this, it’s advised that all powder or dust should first be cleared away before using a soft, lint-free cloth dampened with mild solvents like ethanol 70% and/or isopropanol to get rid of any sticky matter. Proper maintenance procedures such as cleaning, calibration, and adequate temperature regulation will make sure your balance operates effectively for delivering accurate results.

Customization and Security Features

Analytical balances have taken the lab to a whole new level with customizable features such as user profiles, data storage and retrieval capabilities, calibration options for added accuracy, connectivity and integration. This provides maximum flexibility in performing weighing operations while safeguarding sensitive information from unauthorised access or tampering. Unmatched functionality offered by modern analytical balances makes them ideal tools for precision work where even subtle discrepancies can make all the difference. To their advanced features, these instruments also provide comprehensive security systems including password protection on top of tamperproof physical barriers around its chamber during usage so that results remain accurate each time it is used.

Tailoring Your Balance to Specific Lab Requirements

Analytical balances can be tailored for particular laboratory requirements based on a variety of features and possibilities. This comprises selecting the necessary precision, establishing accuracy demands, while also ruling out any special symmetry needs.

Customization of these analytical scales can bolster lab effectiveness by streamlining processes, augmenting exactness levels and diminishing external disturbance.

Prioritizing Equipment Security and Integrity

Analytical balances have been designed to be secure with various features. These include a draft shield or weighing chamber, which is used to protect against air currents affecting small samples. There is also an enhanced housing for increased durability and in-built quality assurance safety measures that help ensure reliable operation.

RS232 USB connections should only be employed when the relevant security standards are maintained – this includes calibrating equipment as well as making sure environmental conditions meet requirements so any external influences don’t distort performance of the balancer accuracy nor compromise data integrity.

As such it’s key that when using analytical balances all appropriate protective measurements are taken into consideration including shielding from air flow disturbances surrounding smaller weights by means of shields during their weighing process while also conforming with adequate protection necessary via USB cabling formats to maintain ideal operating results everytime.

Summary

Analytical balances are indispensable in numerous industries for their precise weighing capabilities. These days, these devices boast superior characteristics and capacities that go beyond the basics. They can easily adjust to different measurement units while granting access to more complex tasks. Stainless steel and glass materials guarantee stability and reliability of analytical balance with extra security features customizable according to specific lab needs at hand.

Frequently Asked Questions

What is an analytical balance used for?

An analytical balance is an incredibly precise measuring tool, typically used to determine the mass of materials like solids, powders and fluids. It’s frequently utilized in chemical analysis due to its high accuracy readings up to 0.0001 g.

What is the difference between analytical balance and normal weighing balance?

Analytical balances are preferred for their higher accuracy and sensitivity, perfect for tasks such as sample preparation that require absolute precision. These weighing scales have the capacity to detect even the slightest changes in mass. On the other hand, regular balances may not be able to differentiate miniscule masses but still prove adequate when it comes to more general purposes of weighing materials.

What are the rules in using analytical balance?

When using an analytical balance, it is crucial to follow the right protocol for accurate results. This entails stabilizing the scale prior to taking a reading, safeguarding against air drafts in the environment where measurements are taken and being gentle while placing samples on weighing pans. Calibration of scales needs to be done regularly as well as carefully inspecting readings for any irregularities. By following these steps combinedly, accuracy can be guaranteed when obtaining data from this instrumentation tool.

How accurate is an analytical balance?

Analytical balances are incredibly precise laboratory tools used for weighing, having a capacity of 100-500 g and with an amazing readability as low as 0.1 mg – 0.001 mg. Hence they offer the utmost accuracy when measuring mass in the sub-milligram range.

What factors can influence the precision of analytical balances?

The accuracy and precision of analytical balances can be affected by environmental factors such as air currents, temperature variations, and other physical elements. All these components must be taken into account when handling the use of those particular balances.